Evaluating The Benefits Of 3D Printing In Flat Foot

- Details

- Published: Friday, 03 April 2020 23:00

- Written by Dr.Varun

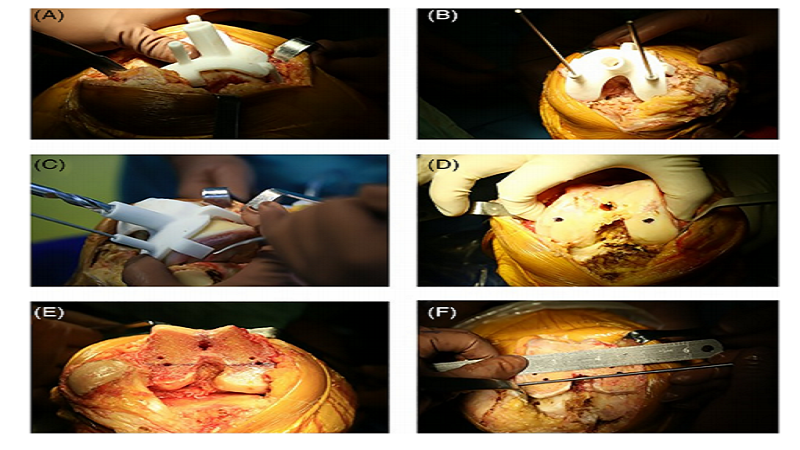

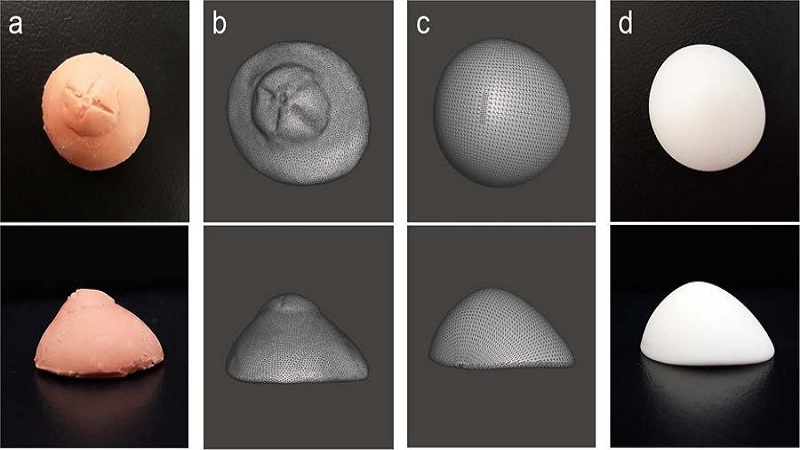

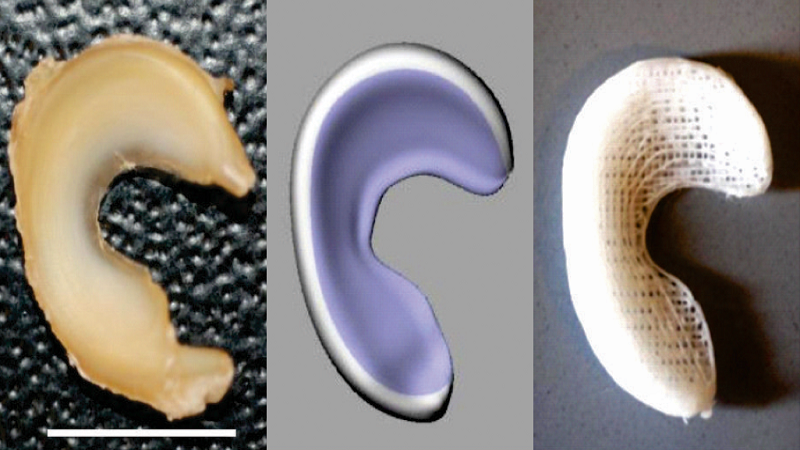

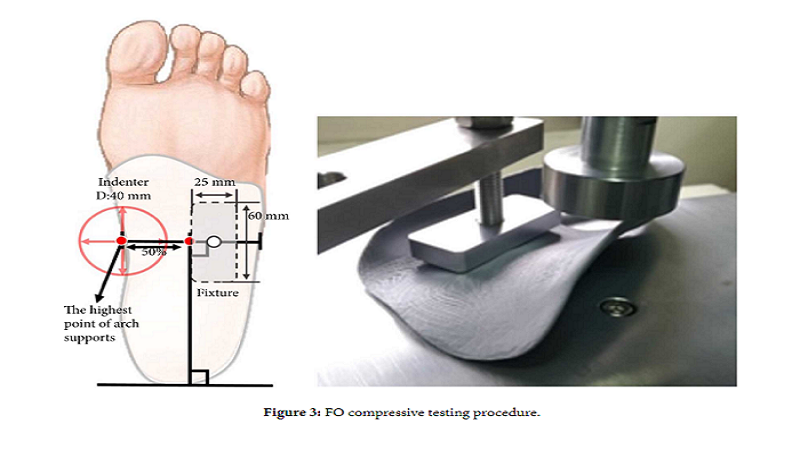

Researchers from Taiwan performed an ANOVA study to determine the effectiveness of 3D Printing in helping people with Flat Foot. 18 Foot Orthoses (FO) samples were 3D Printed at orientations of 0°, 45°, and 90°, and subjected to human motion analysis, with 12 flatfooted individuals. 3D scans of the participants’ feet were exported as an STL file, which was edited with Autodesk Meshmixer software and 3D Printed out of PLA filament on an Infinity X1 FDM 3D printer. The build parameters of the FOs were defined using Ultimaker Cura 3.3 software. The results indicated that the 45° build orientation produced the strongest FOs. In addition, the maximum ankle evertor and external rotator moments under the Shoe+FO condition were significantly reduced by 35% and 16%, respectively, but the maximum ankle plantar flexor moments increased by 3%, compared with the Shoe condition.

Medical 3D Printing & Bioprinting

Medical 3D Printing & Bioprinting