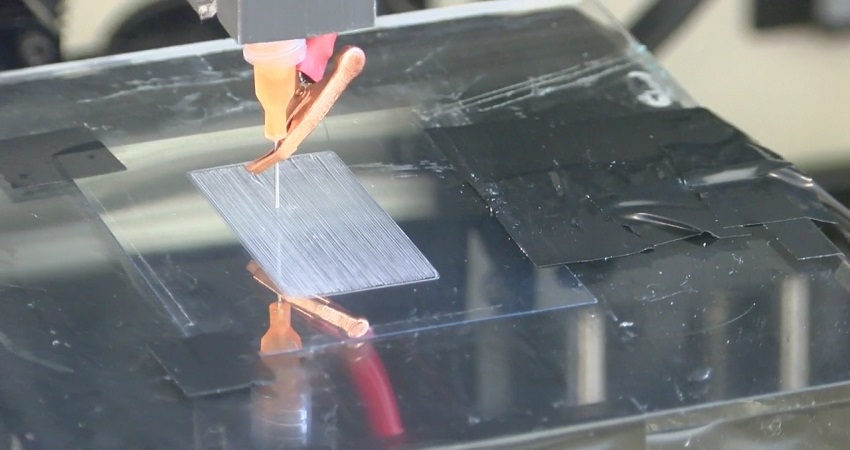

Dr. Christina Salas, PhD, a scientist at the University of New Mexico, is working on 3D Printed Ligaments which can allow for less-invasive surgery, and could be a more permanent solution as the synthetic 3D printed ligament would not wear out or weaken. Using the CT or MRI scan of patient’s damaged joint, an exact replica using 3D Bioprinting can be produced for replacement, and Dr. Salas has received a two-year, $150,000 grant for the research.