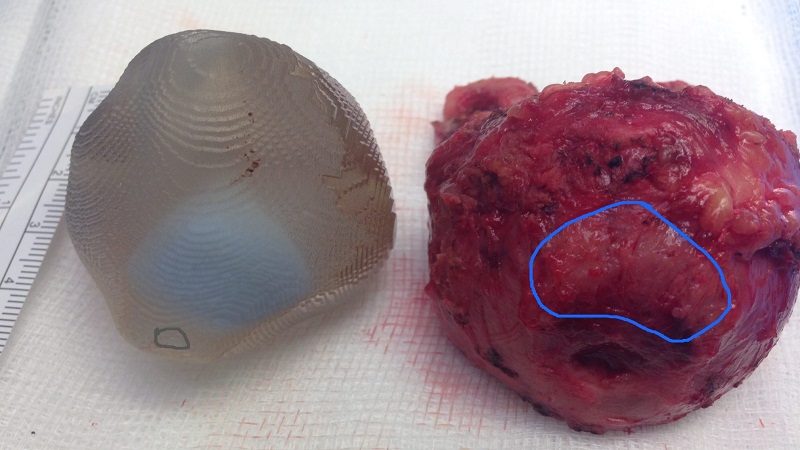

Researchers from China worked towards upgrading the routes of administering Anti-Cancer drugs using 3D Printing. With interstitial permanent radioactive seed implantation, cancer patients can receive large, localized doses for treating tumours. While most seeds are implanted using Ultrasound or CT these days, the research revolved around using 3D-PCT-guided seed implantation, assisted by CT processes, which makes implantation is ‘suitable’ for salvage treatment of recurrent and metastatic solid tumours. The Standard workflows for CT-assisted 3D-PCT-guided seed implantation included: Patient position fixation, CT-simulated positioning, Pre-planning design, 3D-PCT image production, Stabilization by 3D-PCT, Needle puncture for seed implantation, Implantation of seeds and Post-plan evaluation.