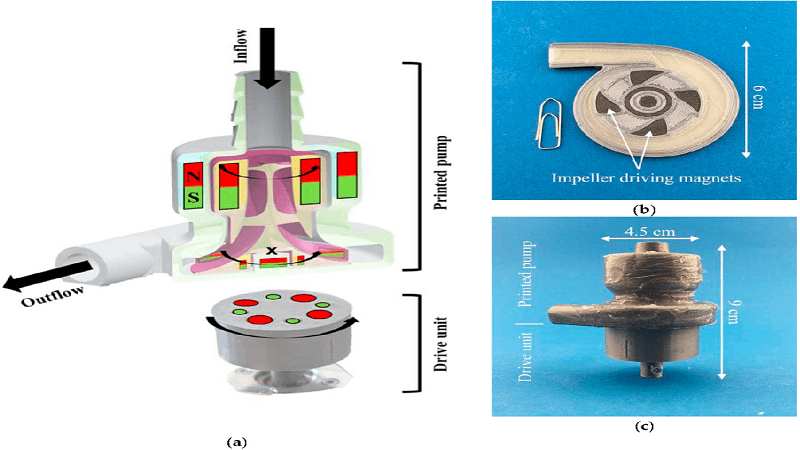

ETH Zurich researchers are working on using 3D Printing Technology to create Magnets that can be used in Rotary Blood Pumps, which are the only option for patients suffering from end-stage heart failure. The traditionally available pumps tend to have the side effects of hemolysis and thrombus formation, therefore they created a filament made from thermoplastic combined with isotropic NdFeB powder, which was then used to 3D print a prototype of a turbodynamic pump with integrated magnets in the impeller and housing. The pump was 3D printed in one piece on a low-cost, consumer-level 3D printer (a Prusa i3 MK2 with a multi-material upgrade, to be exact), then the magnetic components were fully magnetized in a pulsed Bitter coil, added with MagFil, the 3D Printed Magnets, and whole process took 15 hours.