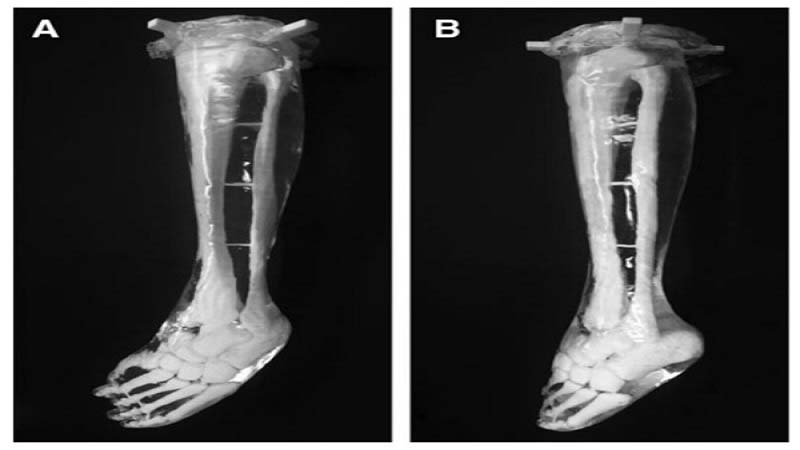

Professor Kenji Shimada and his research team from Carnegie Mellon University’s College of Engineering have developed "Medical Phantom Model" ”, which uses 3D printing to create a realistic looking and feeling hands-on training model for surgeons and by using a clear ballistic gel, a 10% synthetic non-fouling gel material typically used for testing ammunition and to simulate bullet wounds. Currently it is being used for Clubfoot, or Congenital Talipes Equinovarus (CTEV), a congenital deformity which is distinguished by one or both feet being turned inwards and upwards and results in serious mobility problems if left untreated.