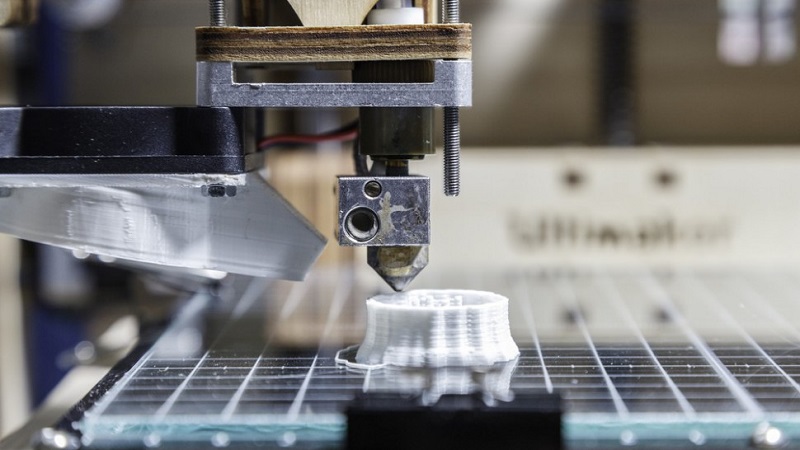

A Research paper was recently published by Preethy Ani Jose, with the Oxford College of Pharmacy, and Peter Christopher GV, from pharmaceutical company Strides Shasun Limited in Bangalore, concerning the challenges faced by Pharmaceuticals when being introduced with 3D Printing. The paper presents regulatory agencies expectations, limitations, problems in establishing such setups for production of drug products, etc. The research paper also discusses how 3D Printing faces challeneges such as proper testing of Design and Manufacturing Process Considerations, validating the 3D printing process and software to determine the level of accuracy, and documentation in order to confirm that any products conform to existing guidelines.