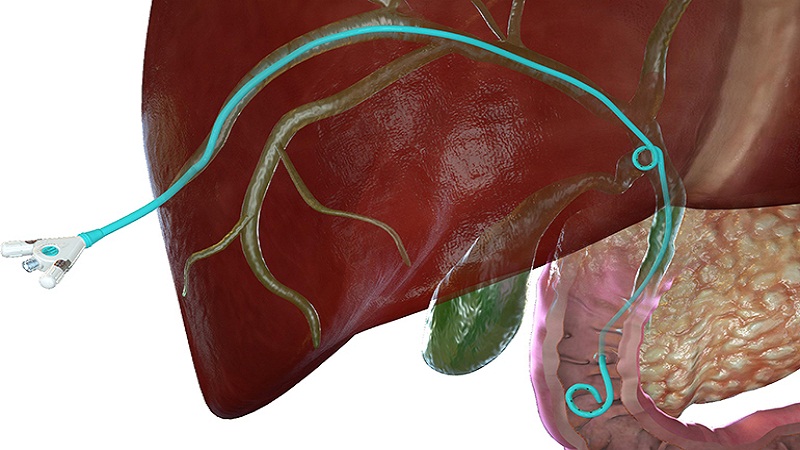

Christen Boyer, a Bioprinting engineer and recent Postdoctoral Fellow at LSU Health Sciences Center in Shreveport, along with vascular cell biologist, tissue engineer, and professor at LSU Health Sciences Center, Steven Alexander; have developed a new technology to 3D Print Polyvinyl Alcohol (PVA) Medical Devices. The method generates biologically compatible 3D printing scaffolds that support cell engraftment because of the high level of protein binding, which is a result of the stabilization process. Working along with Hrishikesh Samant, a transplant surgeon at LSU Health, Boyer and Alexander came up with a novel crosslinked PVA (XL-PVA) 3D printed stent infused with collagen, human placental mesenchymal stem cells (PMSCs), and cholangiocytes. The customized living biliary stents have clinical applications in the setting of malignant and benign bile duct obstructions.