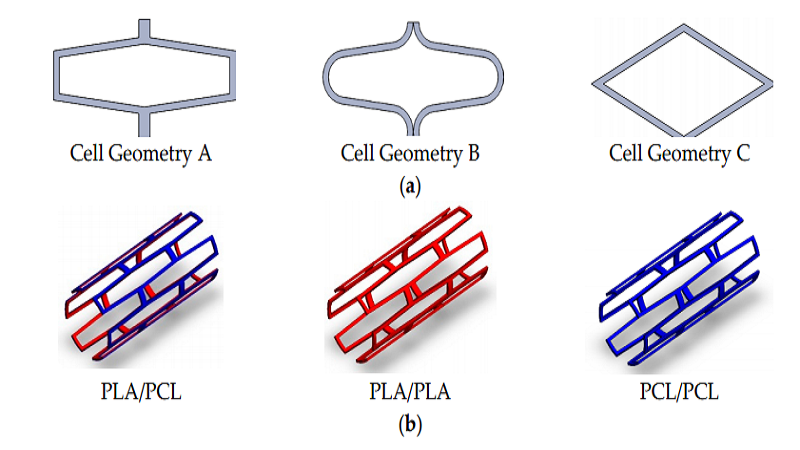

To meet the requirements of a perfect stent like induction of rapid endothelialization to restore the functions of vascular tissue and compliance with medical requirements, particularly the flexibility required to facilitate placement, researchers approached 3D Printing these Stents with PLA and PCL composites. Using Tubular 3D Printer, they 3D Printed the stents which were then seeded with cells and left for three days, and then tests were performed to assess the morphological features, cell proliferation, cell adhesion, degradation rate and radial behavior. Both PCL and PLA showed themselves to be biocompatible, and the composite stents showed the most promise, with medium levels of degradation rates and mechanical modulus.