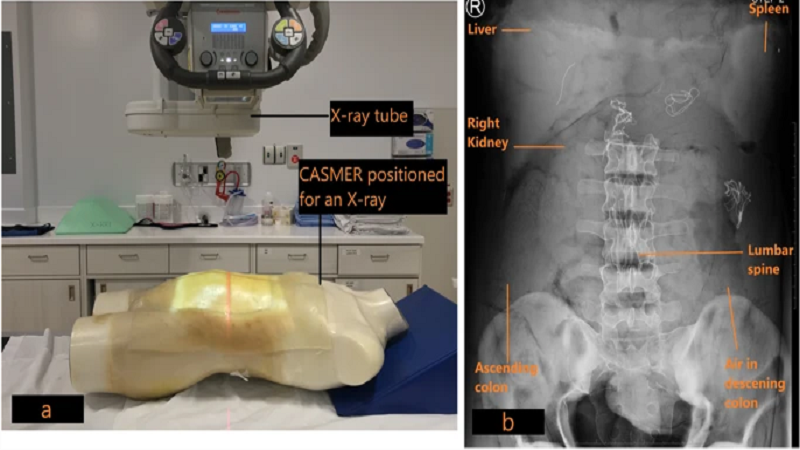

Canadian Researchers used 3D Printing to create Organ Models or Mannequin, called CASMER, which featured both 3D printing of almost all the organ shells, along with added packing material to flesh out the anatomy correctly. This involved four techniques: Realistic 3D printing of abdominal organs, Material-based moulding of the pancreas, Beeswax sculpting of abdominal fat and Off-the-shelf parts for the skeleton and outer shell. Muscle was made from Clear Flex® urethane rubber (Smooth-ON, PA), while fat was created from modelling beeswax. Rostock Max V2 3D printer was used, with source image data converted via segmentation software, as well as open-sourced Slicer.