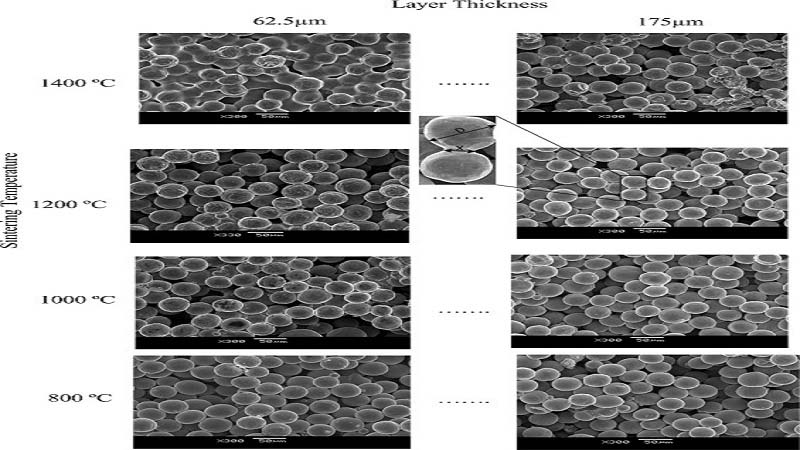

Researchers from the University of Waterloo in Ontario performed a study regarding 3D printing processes with metal and layer thicknesses in material and used Titanium Powder with particle size range of 38–45 μm which was 3D printed on the ZPrinter 310 Plus by 3D Systems . Several different studies considered Particle size, Sintering temperature and Powder compaction level from which they found how layer thickness affects powder compaction during 3D printing, as well as how temperature variations affect bonding and they can now aim to help close any gaps that might occur as implants loosen and cause inflammation and other issues for patients.

Source: http://www.sciencedirect.com/science/article/pii/S0924013616302631

Medical 3D Printing & Bioprinting

Medical 3D Printing & Bioprinting