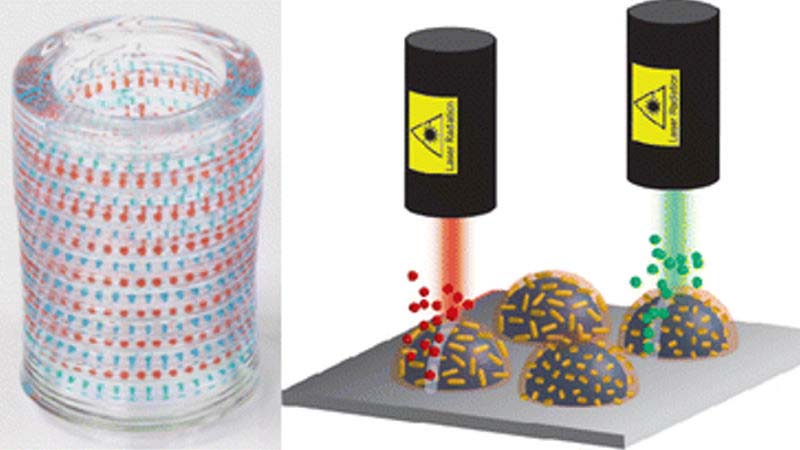

Two universities are working together in creating a new 3D printed therapeutic drug that is loaded with biomolecules and encased in “highly monodisperse core/shell capsules.”

Michael McAlpine is an associate professor in mechanical engineering at the University of Minnesota and at Princeton University who is currently collaborating with researchers from Washington University in St. Louis. Together, they have just published a paper in Nano Letters on the subject: “3D Printed Programmable Release Capsules.”

“This work provides a promising solution to generating multiplexed spatiotemporal molecular gradients in 3D architectures, which is significant to mimic the dynamic microenvironment surrounding cells in natural tissues, as living organisms guide tissue development through highly orchestrated gradients of biomolecules that direct cell growth, migration, and differentiation in 3D matrices,” says Fanben Meng, a postdoctoral researcher in McAlpines Lab.

Their breakthrough offers a ‘powerful new tool’ because of the following specific features:

- Highly monodisperse capsules

- Efficient casing for payloads

- Precise patterning of capsule arrays

- Flexible and programmable reconfiguration of gradients

- Versatility in hierarchical architectures

“Our work was motivated by the fact that living systems utilize exquisite control of biomolecular gradients to control cell fate and ultimately enable complex functional tissues,” says McAlpine. “We believe that replicating such control is a key to many future advances in bioengineering.”

“There has been tremendous prior work on utilizing microfluidics, particle encapsulation, and stimuli-responsive materials to address some of these challenges,” he adds. “Our findings offer a novel perspective by offering a 3D printing based approach to solve these challenges, which has advantages in precision control over volumes, spatial distributions, and diversity of materials including nanomaterials and biomolecules.”

Medical 3D Printing & Bioprinting

Medical 3D Printing & Bioprinting